Skill Saw Mastery: The Ultimate Power Tool Guide You Need 2026

Introduction

Walk into any construction site or woodworking shop, and you’ll hear the distinctive whine of a skill saw cutting through material. This iconic power tool has become synonymous with circular saws themselves, much like how “Kleenex” represents all facial tissues. The skill saw revolutionized carpentry when it first appeared, and it remains an essential tool for professionals and DIY enthusiasts alike.

Whether you’re building a deck, framing a house, or tackling weekend projects around your home, understanding the skill saw is crucial. This portable circular saw puts incredible cutting power in your hands, allowing you to make precise cuts through lumber, plywood, and other materials with speed and accuracy. However, the tool’s power demands respect and proper knowledge to use safely and effectively.

In this comprehensive guide, you’ll discover everything about the skill saw from its history and types to safety practices and advanced techniques. We’ll cover how to choose the right model, maintain it properly, and make cuts like a seasoned carpenter. By the end, you’ll have the confidence to pick up this powerful tool and put it to work.

What Exactly Is a Skill Saw?

The term “skill saw” has an interesting origin story. SKIL Power Tools invented the first portable circular saw in 1924, creating a tool that would transform the construction industry. The SKIL brand became so dominant that people started calling all handheld circular saws “skill saws,” regardless of manufacturer.

Technically speaking, a skill saw is a circular saw with a toothed blade that rotates at high speed to cut through materials. The motor sits above or behind the blade, and you guide the tool along your cutting line. Most models are designed for right-handed operation, though left-handed versions exist.

The tool’s portability changed everything for carpenters. Before portable circular saws, workers had to bring materials to stationary table saws or cut by hand. The skill saw brought the cutting power to the work, dramatically increasing efficiency on job sites.

Today, the SKIL brand still produces circular saws, but many other manufacturers make excellent models. When people say “skill saw,” they usually mean any handheld circular saw, not specifically the SKIL brand. This guide uses the term in that broader, common usage sense.

Types of Circular Saws You Should Know

While “skill saw” often refers to standard sidewinder circular saws, understanding the different types helps you choose the right tool for your needs.

Sidewinder Circular Saws

The sidewinder is what most people picture when they think of a skill saw. The motor sits perpendicular to the blade on the right side. This design makes the tool lighter and more compact than other types.

Sidewinders typically spin the blade faster than worm drive saws, usually between 5,000 and 6,000 RPM. This speed makes them excellent for cutting sheet goods and cross-cutting framing lumber. The lighter weight reduces fatigue during long cutting sessions.

Most DIY homeowners and many professional carpenters prefer sidewinders. They’re generally less expensive than worm drive models. The compact design also makes them easier to handle in tight spaces or overhead cutting situations.

Worm Drive Circular Saws

Worm drive saws place the motor behind the blade in line with it. A worm gear transfers power from the motor to the blade. This design creates a longer, narrower tool profile.

The worm drive configuration produces more torque at lower RPMs, typically around 4,500. This torque advantage helps when cutting dense materials or making long rip cuts through thick lumber. The motor position also provides better sight lines for left-handed users.

Professional framers often prefer worm drive saws. The extra torque powers through tough cuts without bogging down. However, worm drives are heavier and more expensive than sidewinders. They also require gear oil maintenance that sidewinders don’t need.

Cordless Circular Saws

Battery-powered circular saws have improved dramatically in recent years. Modern lithium-ion batteries provide enough power for serious work, not just light duty tasks. You’ll find both sidewinder and worm drive styles in cordless versions.

The obvious advantage is portability without cords. You can work anywhere without finding outlets or managing extension cords. This freedom is invaluable on job sites without power or when working on roofs and other remote locations.

Battery life and power remain considerations. High-capacity batteries add weight and cost. For sustained heavy cutting, corded saws still have advantages. But for many applications, cordless skill saws now perform comparably to corded models.

Specialty Circular Saws

Several specialized circular saws serve specific purposes. Track saws run along guide rails for ultra-precise cuts in sheet goods. Mini circular saws offer compact size for small projects and tight spaces. Concrete saws use diamond blades to cut masonry and stone.

Hypoid saws split the difference between sidewinders and worm drives, offering good torque in a more compact package. Each specialty saw addresses particular needs, though a standard skill saw handles most common cutting tasks.

Key Features to Look for in a Skill Saw

When shopping for a circular saw, several features affect performance, safety, and ease of use.

Motor Power and Speed

Motor power is measured in amps for corded saws and volts for cordless models. Most corded skill saws run between 10 and 15 amps. Higher amperage generally means more cutting power, though motor efficiency matters too.

For cordless saws, 18V and 20V batteries are common. Some professional models use 60V or even higher for maximum power. Match the power level to your intended use. Light duty work doesn’t require maximum power, but serious framing benefits from it.

Blade speed, measured in RPM, affects cutting performance. Faster speeds work well for cross-cutting and sheet goods. Slower speeds with more torque suit ripping thick lumber. Some saws offer variable speed control for different materials.

Blade Size and Cutting Capacity

The most common skill saw blade size is 7-1/4 inches in diameter. This size cuts through 2x material at 90 degrees and handles most framing and general carpentry tasks. The cutting depth adjusts, typically offering around 2-3/8 inches at 90 degrees.

Smaller 6-1/2 inch saws are lighter and work well for DIY projects. They cut up to about 2-1/8 inches deep at 90 degrees, which handles 2x4s and similar materials. Larger 10-inch and 12-inch saws exist for heavy timber cutting but are less common.

The saw also bevels for angled cuts. Most models bevel to 45 degrees, some to 50 or even 55 degrees. Check the bevel capacity at the base to ensure it meets your needs for angled cuts.

Safety Features

Modern skill saws include several safety features. Blade guards automatically retract when cutting and snap back to cover the blade when you’re not actively cutting. This guard is essential for preventing accidental contact with the spinning blade.

Electric brakes stop the blade quickly when you release the trigger. This feature significantly reduces the time the blade spins after cutting, improving safety. Most quality saws now include electric brakes as standard equipment.

Some saws feature anti-kickback mechanisms. Kickback happens when the blade binds in the material and the saw jumps backward toward you. While proper technique is the best prevention, mechanical features can help reduce kickback severity.

Ergonomics and Handling

A comfortable skill saw reduces fatigue and improves control. Look for handles with good grip texture and ergonomic shaping. Some saws have auxiliary handles for two-handed operation, which provides better control.

Weight distribution affects handling. A well-balanced saw feels more controllable and causes less fatigue. Pick up different models if possible to compare how they feel. What’s comfortable varies by personal preference and hand size.

The baseplate or shoe should be sturdy and flat. Cast or stamped metal baseplates are more durable than plastic. The shoe needs to slide smoothly across materials while providing stable support for the saw.

Essential Skill Saw Safety Practices

The skill saw’s power makes safety absolutely critical. Following proper safety procedures prevents serious injuries.

Personal Protective Equipment

Always wear safety glasses or goggles when operating a skill saw. Flying sawdust and debris can damage your eyes. Regular glasses aren’t enough because they don’t provide side protection. Get proper safety eyewear and wear it every time.

Hearing protection is also important. Circular saws produce noise levels that can damage hearing with prolonged exposure. Foam earplugs or over-ear protectors both work well. Don’t skip this protection because damage accumulates over time.

Wear close-fitting clothing without loose sleeves or drawstrings that could catch in the blade. Remove jewelry, especially rings and bracelets. Tie back long hair. These simple steps prevent entanglement accidents.

Work gloves are situational. They protect your hands when handling rough lumber but can reduce feel and control when operating the saw. Many professionals don’t wear gloves while cutting, only when handling materials.

Before You Start Cutting

Inspect your skill saw before each use. Check that the blade guard moves freely and returns to the closed position. Look for damaged or missing teeth on the blade. Ensure all adjustment levers and screws are tight.

Verify that the blade is installed correctly and tight. A loose blade can come off during operation with catastrophic results. The blade teeth should point forward in the direction of rotation. This seems obvious but gets reversed surprisingly often.

Check your work area for hazards. Remove any obstacles from your cutting path. Make sure your power cord is positioned where you won’t cut through it. Clear away sawdust and debris that could cause slipping or tripping.

Secure your material properly. The piece must be well supported on both sides of the cut. Unsecured or poorly supported material can bind the blade or fall unexpectedly. Use sawhorses, clamps, or other supports as needed.

Operating Safety Rules

Keep both hands on the saw when cutting. One hand on the main handle, the other on the auxiliary handle or front of the saw. This provides maximum control and keeps your hands away from the blade path.

Never reach under the material you’re cutting while the blade is spinning. If you need to support material from below, wait until the blade completely stops. This rule prevents serious hand and finger injuries.

Let the saw reach full speed before starting the cut. Don’t force the saw through the material. Apply steady, moderate pressure and let the blade do the work. Forcing causes blade binding, motor strain, and kickback risk.

Stay alert and focused while cutting. Don’t operate power tools when tired, distracted, or under the influence of anything that impairs judgment. Taking a break is always better than having an accident.

How to Make Basic Cuts with a Skill Saw

Mastering fundamental cuts forms the foundation of skill saw proficiency.

Cross Cutting

Cross cutting means cutting across the grain of lumber. This is the most common type of cut when working with dimensional lumber like 2x4s and 2x6s. Mark your cut line clearly with a pencil and square.

Position the saw shoe against the material with the blade aligned just on the waste side of your line. The blade removes about 1/8 inch of material, so accounting for this kerf keeps your piece at the correct length.

Start the saw and let it reach full speed. Guide it steadily along your line, watching the guide notch on the front of the shoe. Keep the baseplate flat against the material. Don’t stop in the middle of the cut if possible.

As you near the end, support the waste piece or have a helper hold it. Unsupported waste can break off and tear the wood or pinch the blade. Complete the cut, then release the trigger and wait for the blade to stop.

Rip Cutting

Ripping means cutting along the grain, usually to reduce the width of a board or sheet. These cuts are typically longer than cross cuts. For long rips, use a rip fence or guide to keep your cut straight.

Many skill saws include a rip fence that attaches to the shoe. You set the fence to the desired width and run it along the edge of the material. This ensures a parallel cut. For wider rips beyond the fence capacity, clamp a straight edge to guide the saw.

Ripping requires more power than cross-cutting because you’re cutting more material. Feed the saw steadily but don’t force it. If the motor bogs down, you’re pushing too hard. Let the saw work at its own pace.

Long rip cuts can cause the kerf to close behind the blade, leading to binding and kickback. Sometimes inserting a small wedge in the kerf behind the blade prevents this closing. Support long pieces so they don’t sag and pinch.

Bevel and Angle Cuts

Bevel cuts angle through the thickness of the material. The skill saw’s baseplate tilts to create this angle. Loosen the bevel adjustment, set the desired angle using the scale, and tighten the adjustment securely.

Common bevel angles include 22.5 degrees and 45 degrees for miter joints and chamfers. Check your angle setting with a protractor or bevel gauge if precision matters. The saw’s scale gives you a starting point but may need fine-tuning.

Bevel cutting reduces the effective cutting depth. At 45 degrees, you lose about 30 percent of the maximum cutting depth. Make sure your saw can cut completely through the material at your chosen bevel angle.

The technique for bevel cutting is similar to straight cuts. The saw may feel less stable due to the angled baseplate. Take extra care to keep the shoe flat against the material and the cut line aligned with your mark.

Advanced Skill Saw Techniques

Once you’ve mastered basic cuts, these advanced techniques expand your capabilities.

Plunge Cutting

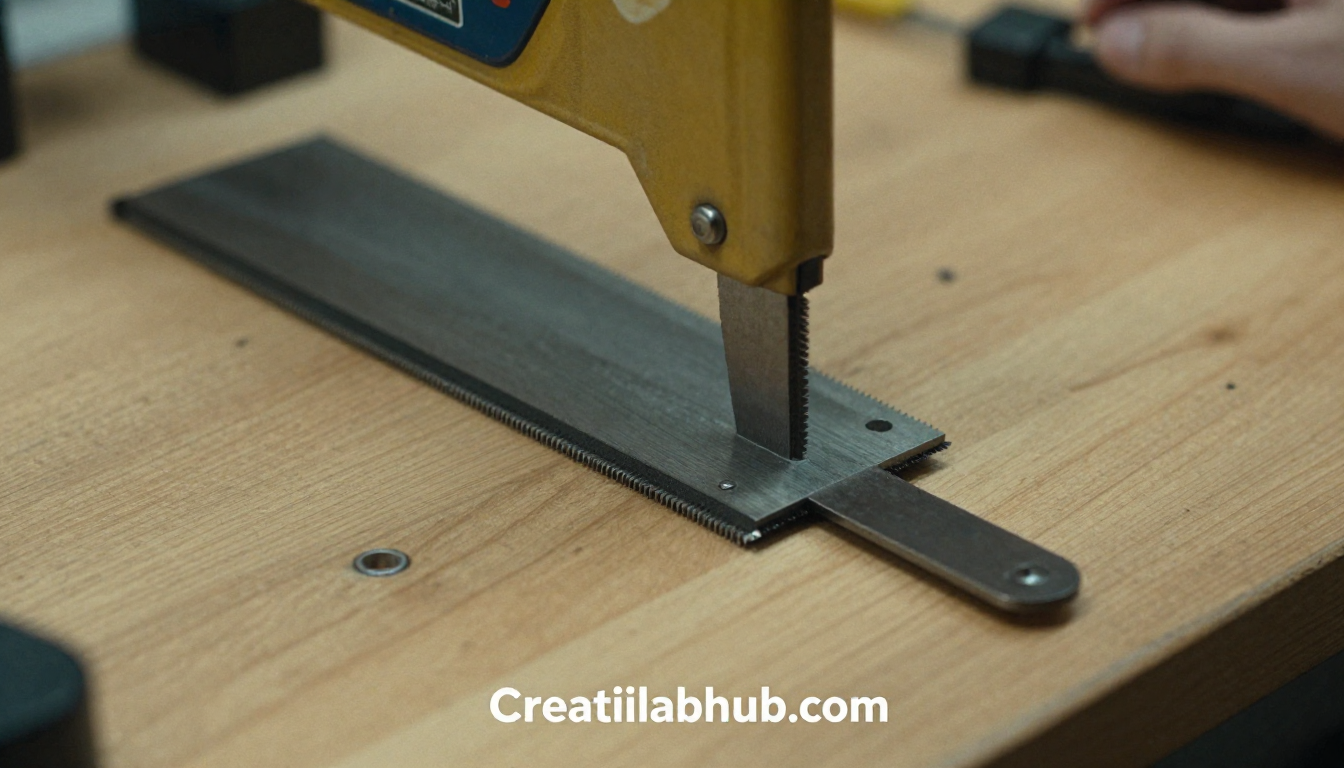

Plunge cuts start in the middle of a board rather than at an edge. You might need this for cutting openings or notches. This technique requires care because you’re controlling the blade guard manually.

Retract the blade guard with the lever while keeping your hand well away from the blade path. Tilt the saw forward on the front of its shoe with the blade clear of the material. Start the saw and carefully lower the blade into your starting point.

As the blade cuts through, gradually lower the saw until the shoe sits flat on the material. Release the guard lever so it can function normally. Complete the cut to your end point, then turn off the saw.

Plunge cutting is more dangerous than standard cutting because you’re manually controlling the guard. Take extra care and never rush. Practice on scrap material before attempting plunge cuts on your actual project.

Cutting Sheet Goods

Cutting large sheets of plywood or OSB presents challenges because of the size and weight. Support the sheet well so it doesn’t sag or move during cutting. Sawhorses positioned correctly make this easier.

For long, straight cuts across a full sheet, clamp a straight edge to guide your saw. A level, straight 2×4, or dedicated cutting guide works well. This ensures accuracy over the long distance where freehand cutting would likely wander.

Set the blade depth to just slightly more than the sheet thickness. This minimizes tearout on the bottom surface and is safer than having excessive blade projection. The saw cuts efficiently with minimal waste.

Consider which side faces up. The skill saw’s blade rotates upward through the material, so tearout occurs on the top surface. Place the good face down if appearance matters, or apply painter’s tape along the cut line to reduce splintering.

Cutting Metal and Other Materials

With the right blade, your skill saw cuts materials beyond wood. Metal-cutting blades with carbide or special teeth cut aluminum, steel, and other metals. Make sure you get a blade designed specifically for metal cutting.

Cutting metal requires different technique than wood. Use slower feed rates and let the blade work without forcing. Metal generates heat, so the blade and material get hot. Let them cool before handling.

Plastic materials like PVC pipe cut easily with a wood blade. The key is supporting the round pipe so it doesn’t roll during cutting. Use V-blocks or a simple jig to hold pipe securely. Fiber cement siding requires a specialized blade and proper dust control because the dust is hazardous.

Maintaining Your Skill Saw for Longevity

Proper maintenance keeps your skill saw running smoothly and safely for years.

Blade Care and Replacement

Keep your blade sharp and clean. A dull blade requires more force, cuts poorly, and increases kickback risk. If you notice the saw binding more or leaving rough cuts, the blade probably needs attention.

Clean pitch and resin buildup from the blade with a commercial blade cleaner or oven cleaner. Lay the blade flat in a shallow pan with cleaner, let it sit according to product directions, then scrub with a brush and rinse clean.

Sharpen carbide-tipped blades professionally. The cost is usually less than buying a new quality blade. Steel blades can be sharpened but are often inexpensive enough to simply replace when dull.

Replace damaged blades immediately. Missing teeth, cracks, or warping make the blade unsafe. Store blades properly to prevent damage. Blade guards or cases protect teeth from impacts that break or dull them.

General Maintenance Tasks

Keep the saw clean, especially the blade guard mechanism and moving parts. Sawdust accumulation can prevent the guard from functioning properly. Blow out dust with compressed air or wipe with a brush after each use.

Check the baseplate for flatness and squareness. If the saw has been dropped or heavily used, the shoe might not be perfectly flat or square to the blade. This affects cut quality. Most baseplates can be adjusted if needed.

For worm drive saws, check and change the gear oil according to the manufacturer’s schedule. Low or dirty oil damages the gears. The oil level sight glass makes checking easy. Use only the recommended oil type.

Inspect the power cord regularly for damage. Cuts, cracks, or exposed wires create shock and fire hazards. Replace damaged cords immediately. For cordless saws, maintain batteries properly by following charging instructions and storing them correctly.

When to Seek Professional Service

Some issues require professional repair. If the motor makes unusual noises, smells like burning, or loses power, internal problems may exist. Continuing to use a damaged motor risks further damage or safety hazards.

Electrical issues beyond simple cord damage need professional attention. Problems with switches, internal wiring, or the motor itself require someone qualified to work on power tools safely. Don’t attempt electrical repairs unless you have the proper training.

If the saw produces excessive vibration, something is wrong. This could indicate a bent arbor (the shaft the blade mounts on), bad bearings, or other mechanical issues. Excessive vibration makes the saw hard to control and potentially dangerous.

Choosing the Right Skill Saw for Your Needs

With so many models available, selecting the right saw depends on how you’ll use it.

For Homeowners and DIY Users

Occasional users doing home projects don’t need the same tool as professional contractors. A quality sidewinder circular saw with a 7-1/4 inch blade handles most homeowner tasks. Look for a reputable brand with good reviews rather than the cheapest option.

Cordless models make sense for homeowners who value convenience over absolute power. Battery compatibility with other tools you own matters. Buying into a battery platform that serves multiple tools provides better value than mixing battery systems.

Safety features become especially important for less experienced users. Look for electric brakes, good blade guards, and clear safety instructions. Spending a bit more for better safety features is worthwhile.

A mid-range saw from a quality manufacturer serves most DIY needs well. You don’t need to buy the most expensive professional-grade saw, but avoiding the cheapest budget options usually pays off in reliability and safety.

For Professional Contractors

Professionals need tools that withstand daily demanding use. Durability, power, and long-term reliability justify higher prices. The saw is a business tool that needs to work when you need it.

Many professional framers and carpenters prefer worm drive saws for their torque and durability. However, plenty of pros use sidewinders very successfully. Personal preference and the specific work you do should guide this choice.

Corded saws still make sense for some professional applications where maximum power and unlimited runtime matter. However, high-end cordless models now serve many pros well, especially when working on sites without power.

Consider the cost of ownership, not just purchase price. A more expensive saw that lasts longer and requires less maintenance may cost less over its lifetime than cheaper models you replace frequently. Warranty support matters when the tool is critical to your business.

Common Skill Saw Problems and Solutions

Even well-maintained saws occasionally have issues. Knowing how to troubleshoot saves time and frustration.

The Saw Won’t Start

First, check the obvious. Is it plugged in? Is the outlet working? For cordless saws, is the battery charged and properly seated? These simple issues cause most start failures.

If power is reaching the saw but it won’t run, the trigger switch might be faulty. Some saws have safety switches that must be pressed along with the trigger. Make sure you’re engaging all necessary switches.

The motor’s internal thermal overload protection might have tripped if the saw overheated. Let it cool completely for 15 to 30 minutes, then try again. If thermal shutdown happens frequently, something is causing the motor to work too hard.

Brushes in the motor wear out eventually. If the saw is old and runs little or not at all, worn brushes might be the issue. Many saws have replaceable brushes that are relatively inexpensive. Check your manual for brush inspection and replacement instructions.

Blade Binding or Kickback

Blade binding and kickback usually result from improper technique or setup. Make sure material is properly supported on both sides of the cut so the kerf doesn’t close. Support prevents the material from pinching the blade.

Check that the blade is sharp and appropriate for the material. A dull blade or wrong blade type requires excessive force and binds easily. Installing the blade backward also causes binding and terrible cut quality.

Don’t twist the saw during a cut trying to follow a wandering line. This causes binding. If you veer off your line, complete the cut, then start a new one. Or back the saw out carefully while it’s still running and realign.

Cutting wet or green lumber increases binding because the wood is more prone to closing around the blade. Allow lumber to dry when possible or work extra carefully with green wood. Making relief cuts can help with particularly problematic pieces.

Poor Cut Quality

Rough, splintered cuts usually indicate a dull blade. Blades dull gradually, so you might not notice the declining quality until it’s quite bad. Fresh sharp blades make noticeably cleaner cuts.

Cutting too fast also produces rough cuts. Slow your feed rate and let the blade cut at its natural pace. Forcing the saw through material faster than the blade can cleanly cut leaves ragged edges.

Using the wrong blade type affects cut quality. Ripping blades have fewer, larger teeth for fast cutting along the grain. Crosscut blades have more, smaller teeth for smoother cuts across grain. Combination blades try to do both adequately but excel at neither.

Vibration from a damaged blade, bent arbor, or worn bearings produces poor cuts. Check the blade for damage and make sure it’s mounted properly. Excessive vibration needs professional diagnosis to identify the cause.

Conclusion

The skill saw remains one of the most versatile and essential power tools in any workshop or job site. From its invention by SKIL in 1924 to modern cordless models, this tool has continuously evolved while maintaining its core purpose: providing portable, powerful cutting capability. Understanding the different types of circular saws, essential features, and proper techniques helps you choose the right tool and use it effectively.

Safety must always come first when operating a skill saw. The tool’s power and exposed blade demand respect and proper handling. Following safety guidelines, wearing appropriate protective equipment, and maintaining your saw properly prevents accidents and extends tool life. Whether you’re a weekend DIYer or professional contractor, these practices apply equally.

Mastering the skill saw takes practice, but the techniques you’ve learned here provide a solid foundation. Start with basic cross cuts and rips, then progress to more advanced techniques as your confidence grows. Which project will you tackle first with your new skill saw knowledge? Share this guide with someone learning to use power tools, or bookmark it for reference the next time you need a refresher on proper technique.

Frequently Asked Questions

What is the difference between a skill saw and a circular saw?

There is no functional difference. “Skill saw” is a brand name that became generic, like “Kleenex” for tissues. SKIL invented the first portable circular saw in 1924. People now use “skill saw” to refer to any handheld circular saw regardless of brand.

What size skill saw blade should I buy?

For most general construction and woodworking, a 7-1/4 inch blade is standard. This size cuts through 2x lumber and handles most common tasks. Smaller 6-1/2 inch saws work well for lighter duty projects, while larger blades suit heavy timber cutting but are less common and harder to handle.

Can a skill saw cut through metal?

Yes, with the proper blade. Metal-cutting circular saw blades have special teeth designed for cutting aluminum, steel, and other metals. Never use a wood-cutting blade on metal as it will quickly dull or break. Use slower feed rates when cutting metal and let the blade cool between cuts.

How deep can a skill saw cut?

A standard 7-1/4 inch skill saw typically cuts about 2-3/8 inches deep at 90 degrees. This depth decreases when you bevel the blade for angled cuts. At 45 degrees, expect roughly 1-5/8 inches of cutting depth. Larger blades cut deeper, while smaller 6-1/2 inch blades cut to about 2-1/8 inches.

Why does my skill saw kickback?

Kickback occurs when the blade binds in the material and the saw jumps backward. Common causes include improper material support allowing the kerf to close, using a dull blade, forcing the saw too hard, twisting during a cut, or cutting into knots or nails. Proper technique and sharp blades prevent most kickback incidents.

How often should I replace my skill saw blade?

Replace blades when they become dull, damaged, or no longer cut cleanly. How often depends on usage and materials cut. Professional contractors might replace blades weekly or monthly with heavy use. Homeowners doing occasional projects might use the same blade for years. Clean and inspect blades regularly to assess condition.

Is a cordless or corded skill saw better?

Both have advantages. Corded saws provide unlimited runtime and consistent maximum power, ideal for heavy sustained cutting. Cordless saws offer portability and convenience without managing cords. Modern cordless saws perform well for most tasks. Choose based on your typical work environment and cutting demands.

What safety equipment do I need when using a skill saw?

At minimum, wear safety glasses or goggles to protect your eyes from flying debris. Hearing protection prevents hearing damage from the saw’s noise. Work boots with steel toes protect feet if you drop the tool. Avoid loose clothing, tie back long hair, and remove jewelry. Gloves are optional but many users prefer the better feel without them.

Can I use a skill saw to cut curves?

Skill saws are designed for straight cuts only. The circular blade and rigid baseplate make curved cutting impossible. For curves, use a jigsaw, bandsaw, or reciprocating saw depending on the material thickness and curve tightness. The skill saw excels at straight cutting through its design.

How do I keep my skill saw cuts straight?

Mark your cut line clearly with a pencil and square. Align the guide notch on the saw’s shoe with your line. Keep the baseplate flat against the material and watch the guide notch throughout the cut. For long cuts, clamp a straightedge guide to the material and run the saw’s baseplate along it for perfect accuracy.